The continuous improvement process is an interesting option for improving the services, products or management methods of an organization. Discover the different options available to you to make your work environment even more efficient and productive.

Continuous improvement… more specifically

It is a process of progressive and/or perpetual change, aimed at optimizing the efficiency of operations within an organization. This can be done for minor improvements that can be made at regular intervals or as a set of adjustments that can be applied to an entire system. An action plan can be designed as a series of steps for one or more teams.

This process ofcontinuous improvement can become multifunctional, for example when it concerns different management systems (quality management, human resources management, programme or project management, etc.). Practicality, efficiency and flexibility of operations are aspects that need to be constantly reassessed and, if necessary, improved. Especially when they involve relationships with customers, suppliers and employees.

5 ways to integrate continuous improvement into your organization

1. Implement the Kaizen method

The term comes from “kai”, a Japanese word meaning change, and “zen”, which refers to what is good and improved. The kaizen method became popular after the publication of Imai Mazaaki’s book “The Key to Japanese Competitiveness”. Its main objective is to maximize productivity and efficiency. The principles underlying this method are as follows:

- process self-assessment,

- the use of existing skills,

- Efficiency (through the reduction and elimination of inefficient operations),

- the importance of incremental change, which emphasizes small, continuous positive changes rather than one big success.

2. Use the 5 S’s method

This other solution, which also comes from Japan, is based on 5 principles: sort, tidy, repair, order and be rigorous. In Japanese, each of these terms begins with the letter “S”. This method is designed to minimize the loss of data, clutter, damage, or work accidents in an organization. The 5 S’s method must be planned and constantly monitored to ensure that its rules are followed. It has the advantage of improving working conditions as well as productivity.

3. Implementing Lean Management

Inspired by the methods mentioned above, but closer to the American industrial model, the Lean method aims first of all to eliminate the superfluous and wasteful in each of the company’s operations. To achieve this goal, aspects such as unnecessary overloads, latencies, overproduction are taken into account and analysed through a process mapping and an estimation of their added value. Corrections to these deficiencies must be addressed without delay to achieve continuous improvement.

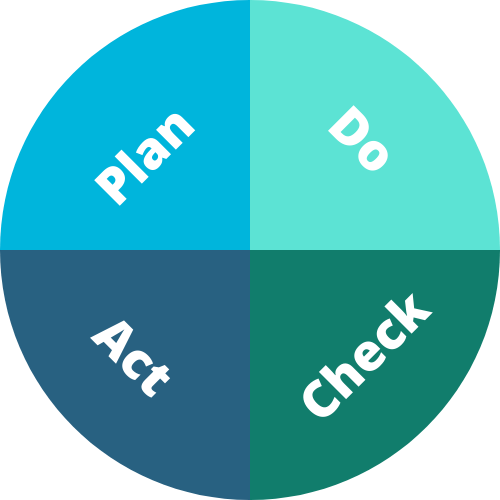

4. Optimize with the PDCA method

This American approach was born in the 1950s under the name Plan Do Check Act (now PDCA). Based on the Deming wheel, a set of measures aimed at continuous improvement defined by indicators, it involves four stages of achievement:- analysis of the situation to be improved and/or the problems to be solved ;

- implementation of a solution based on experiments, improvements and derived approaches;

- concrete evaluation of the results obtained ;

- identification of the aspects to be corrected and of the origin of the errors or deficiencies noted.

5. Set SMART goals

This approach, both qualitative and quantitative, aims to define objectives based on precise indicators at each stage of the production and execution of a project. The use of indicators has become very common in management and marketing, particularly because it allows problems to be identified and avoided from the start. To ensure the success of the approach, however, the nature of the objectives concerned must be specific, measurable, achievable, realistic and defined over time.

A tool to implement

a continuous improvement process?

What are the advantages of a continuous improvement approach?

All continuous improvement process has the main advantage of being able to rectify errors in operations in a progressive manner, without having to shake up the entire organization. It also allows :- ensure greater productivity and efficiency throughout the system;

- save money through awareness of problems (which should not occur again in the future);

- avoid waste and implement improvements to increase satisfaction;

- not having to pay for high-cost consultations, equipment or research, by using the talents and ideas of the existing workforce;

- to implement small incremental changes more easily, as the ideas come from the workers themselves;

- to obtain more motivation from employees;

- to encourage productive teamwork.